Our first test was to fit one of our 10' diameter wind turbines to the engine.

There is almost the full setup up and running. Critical parts not pictured are the pop off valve (the pop off valve is a safety that opens should the boiler get over 100PSI) and the lubricator for the engine that injects oil into the steam line and keeps the cylinder lubricated. Of course lots of other valves, pipes etc. Also pictured above are two drip oilers to keep the crosshead lubricated, a steam gage and a check valve to sit between the injector and the boiler. The injector uses steam to inject hot water into the boiler when running. A steam whistle is a must - this whistle is an 1880's Crane whistle. Pictured above are most of the other bits we need. The boiler is only rated for 100PSI and we'll run it a bit below that so we have some safety factor. We filled it all the way to the top (actually above the top because we put pipes above the boiler) with water, and then put 150PSI air pressure to it and looked for leaks. First step was to hydrostatically test the boiler. It was made by 'The Look Out boiler company' in 1940. I'm guessing it to be about a 4hp boiler. It's in very good shape, I believe it's been rebuilt and never run since. I bought it at auction nearby (stole it) for less than 150. The engine is a 1903 C&BC 6 horsepower steam engine. This project has moved forward slowly over the course of a year as we've gathered all the parts required. I don't need to rely on petroleum - I have lots of wood all around me!

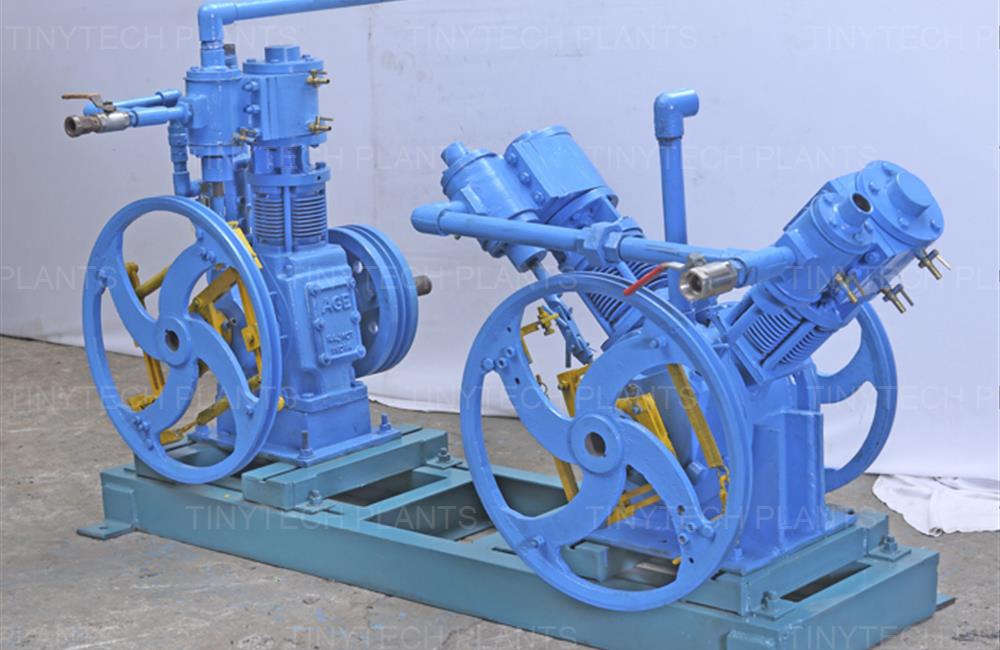

#Steam engine generator#

For the most part we have all the power we could ever need from our small 600 Watt solar array and our 20' diameter wind turbine, but on occasion I do need to run a generator and I always figured that a steam engine would be the most fun, plus.

This page is a diary about our effort to build a steam powered 'backup generator' to charge our batteries.

0 kommentar(er)

0 kommentar(er)